Seasonal Energy Storage

We investigate novel processes for decentralized seasonal energy storage. Our current work focuses on the steam iron process, which allows the safe handling of hydrogen in the form of iron powder.

Contact: Samuel Heiniger

The Challenge: Energy security and self-sufficient energy production have become a key priority in many countries around the world. Recent geopolitical tensions exemplified the undeniable dependence on imported energy for Europe. Natural gas prices reached record prices following the war in Ukraine, showcasing the vulnerability of the energy supply chain. On the other hand, the ever-increasing threat of climate change, strongly encourages an urgent move towards renewable power sources. Solar power in particular, is a promising alternative to fossil fuels and has been chosen by the Swiss federal government as one of the main future power sources with a targeted installation of 35 TWh in 2035. The productivity of solar power, unlike traditional energy sources, is dependent on meteorological conditions and therefore exhibits a seasonal pattern. This leads to a mismatch between supply and demand and creates a fundamental availability issue. This dependence on imported fuels or weather conditions creates a pressing demand for a reliable electricity supply in winter. To prevent blackouts, cost-effective seasonal energy storage technology is therefore highly crucial.

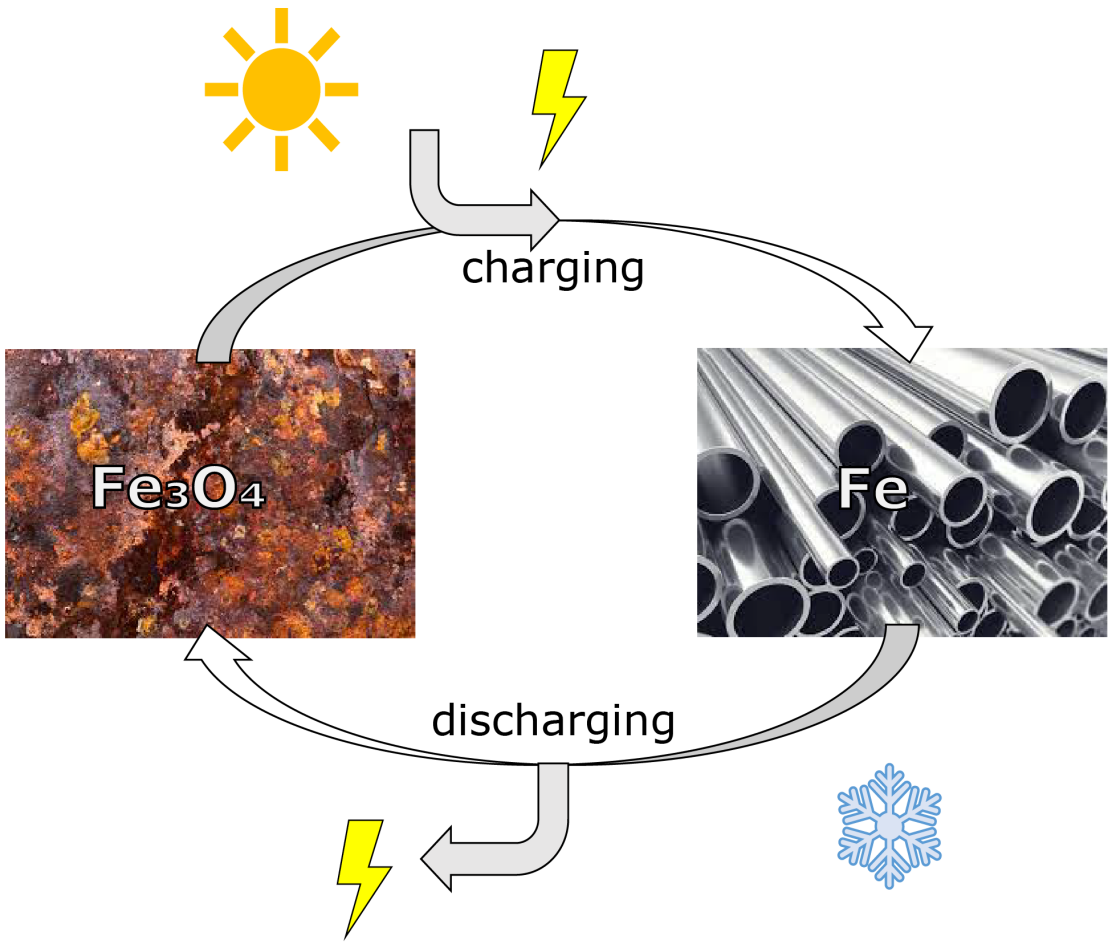

Our Goal: The goal of the project is to demonstrate the feasibility of seasonal energy storage using a redox reaction based on iron and iron oxide (rust). The process allows for the conversion of excess electricity into hydrogen, which is then stored in a solid material for later use. The steam iron process has very low cost, high reliability and low risk, since the very simple process set up requires no expensive, toxic, explosive material and operates at atmospheric pressure.

How it works: During periods of surplus energy production, the excess electricity is converted to hydrogen gas from water through an electrolyzer. The hydrogen gas flows through a reactor filled with iron oxide, which is reduced to iron and the hydrogen gas is oxidized to water. During discharge, when energy is required, the process is run in reverse. Water is evaporated using an electric boiler, and the steam is converted back into hydrogen at temperatures above 150°C. The iron gets re-oxidized to iron oxide, which can be reused for the next storage cycle. The produced hydrogen can then be converted to power or energy, closing the cycle from power to power.

State of research: Originally developed in the early 1900s, the steam iron process has recently gained attention due to the growing demand for clean hydrogen fuel and the need for efficient energy storage solutions. Unlike many other proposed storage systems, it offers simplicity and cost-effectiveness through the use of abundant and non-toxic materials, and safety by design. The process demonstrates high reactivity, and its storage capacity increases with each cycle, making it particularly suitable for long-duration storage over many cycles. Compared to other storage methods the steam-iron process excels in terms of cost-effectiveness, safety and energy density. It presents a promising solution to the challenges of renewable energy storage, especially for seasonal storage needs. To demonstrate the technical feasability of this process, we buildt a 10MWh pilot plant at ETH Hönggerberg. The first charing cycle, using hydrogen to reduce iron oxide to iron, was successfully completed over a time span of 4 months. The discharging cycle is currently ongoing.

Literature: Heiniger, S. P.; Fan, Z.; Lustenberger, U. B.; Stark, W. J., Safe seasonal energy and hydrogen storage in a 1 : 10 single-household-sized pilot reactor based on the steam-iron process. Sustainable Energy & Fuels 2024, 8 (1), 125-132. external pagehttps://doi.org/10.1039/D3SE01228Jcall_made

Contact: Shimon Schweinfurth

Green hydrogen will play a significant role in the future’s energy mix. Seasonal energy storage systems are just one example of how green hydrogen can be used. It can also be used as a feedstock for many industrial processes. We are investigating ways to reduce the cost of water electrolyzers that are needed to produce green hydrogen. Our goal is to accelerate their deployment by focusing on research related to components, cell and stack design, and manufacturing processes.